By Heather Cass, Publications Manager, Penn State Behrend

The School of Engineering’s annual Fasenmeyer Design Conference is a big day for senior engineering student, the culmination of a two-semester capstone project. Faculty, industry sponsors, family, and friends fill the presentation rooms. Students wear suits and aim to impress.

So, when one team’s project literally fell apart outside the classroom minutes before their presentation, you can imagine the panic it induced. The project, months of work, lay in pieces.

Then Chris and Andy Bartlett arrived.

With tools in hand, Penn State Behrend’s resident machinists and problem-solvers dropped to their knees beside the students.

“It was like a NASCAR pit crew in the hallway,” Chris recalls with a laugh.

They got it working. The students presented. The project succeeded.

It’s exactly the kind of moment Chris and Andy relish and show up for—even when they don’t have to.

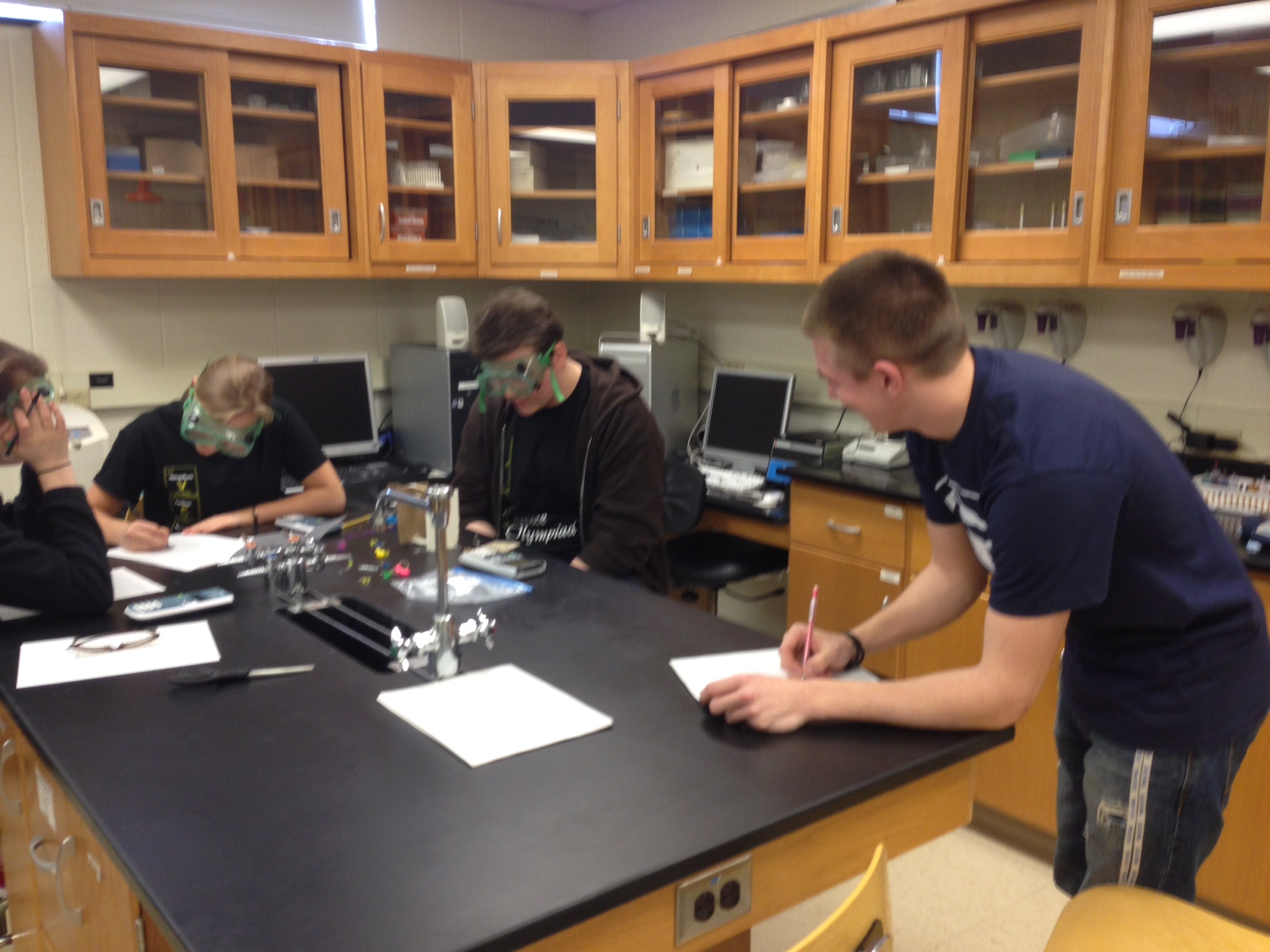

“They don’t have to come in over the weekends to machine parts for the Society of Automotive Engineers (SAE) club’s competition car the week before our competition,” said Hunter Kamensky, a senior Mechanical Engineering Technology major and a member of the club’s executive board. “They didn’t have to become Environmental Health and Safety coordinators of the SAE/Robotics Lab to ensure our safety, and they didn’t have to come to the SAE club’s car-testing day at Lake Erie Speedway to show their support, but they did. They care about students.”

Chris has been at Behrend for five years; Andy, his uncle, for three. Combined, they bring sixty years of tool-and-die industry experience to the School of Engineering.

They also bring a willingness to show up, say yes, and help students turn drawings into reality.

We sat down with Chris and Andy to talk about their work, why manufacturing matters, and what they hope students learn from them.

For someone unfamiliar with machining, how would you describe what you do here day-to-day?

Chris: We make things the engineering students and faculty design.

Andy: We try to help them succeed by giving them the best approaches and let them know when something is not feasible. 3D printing is cool, but it’s fictitious. You can design and build parts with a 3D printer that won’t hold up in the real world.

What kinds of projects do you most often help with? Do any stand out as especially challenging?

Chris: We help with research projects, molds for the Plastics Engineering Technology program, welding, fabrication, capstone projects, and student clubs. We’re big supporters of the clubs because students learn a lot tinkering and working on side projects.

Andy: One of the most challenging projects we work on every year is the Cast in Steel capstone project, where students design and build functional replicas of traditionally forged items using modern steel casting. It’s reverse engineering. You basically have to work backward to create the piece. It’s technical, hands-on, and really fun.

When a student brings you a design that isn’t quite manufacturable, how do you handle it?

Chris: We can usually tell just by looking at plans what will work and what won’t. We mark it up, make suggestions, and show them the empirical data on what they are trying to do and why they need to revise.

Andy: Students do challenge us sometimes. We allow them to think it through or even try it, unless it’s going to be catastrophic. Failure teaches more than success.

The difference for us, having worked years in industry, is that we know manufacturing is inherently challenging. But in the shop, where they’re making a profit, everything has to be perfect. Failure is not something they embrace. The education environment is quite the opposite—we let them think through a bad idea. Then they really understand it.

What do engineering students learn in the shop that they can’t learn in a classroom?

Andy: In manufacturing, you learn that there are things that can be perfect in theory but impractical in real life. Tolerancing is a concept that clicks in the machine shop. The weight of materials and size of parts matter. Plastic is light, steel is very heavy. The physical reality matters.

Chris: Before they get to the machine shop, they’re working on fundamentals and hypotheticals. It’s all theoretical in the classroom, but when they see it, they really get it.

Andy: We have a dozen MET students, mostly seniors, who work with us on a weekly basis now. We wish we could get them in the shop in their first year. It would aid everything they’re learning in the classroom.

Can you share a memorable moment working with students?

Chris: That hallway moment with the senior design team—the NASCAR pit crew moment—that’s one.

Andy: Attending the SAE vehicle club’s training sessions at Lake Erie Speedway. We were testing on the track, doing modifications right there. We try to teach students to stay calm, even when things fall apart—because they will. You can’t be in a panic and do good engineering work.

How does your industry experience influence how you teach and support students?

Andy: At 22, young people tend to think they know everything, but I tell them when they get their first job, try to find a guy who is 50 or 55 and learn as much as you can from him. Those guys have real-world experience. You can learn a lot from them.

We also tell them to work on their interpersonal and teamwork skills, and we just try to instill the reality that manufacturing is hard work, and they will have mundane days. That’s just life.

Chris: We also encourage internships. That real-world experience is invaluable. They’re getting an excellent education at Penn State Behrend, but that physical contact with manufacturing matters.

Safety regulations limit the students’ access to the shop. How have you tried to help maintain hands-on opportunities?

Andy: We started to think about ways that we could legally allow students to work in the shop and have been making some headway. There’s a danger factor. We have limitations we have to work with. There’s a lot of training involved.

We’re very involved in America’s Cutting Edge (ACE), which offers hands-on CNC training at Behrend for students over sixteen. It’s ideal for those who are interested in exploring engineering, manufacturing, or hands-on technical careers.

Chris: ACE gave us the ability to get mechanical engineers on the floor for a forty-hour boot camp. They construct an air engine. In total, we’ve had about sixty students take part in the boot camps.

Andy: We also offer support for the METAL program—a four-day hands-on training experience in casting and forging. The goal of these programs is to get young people involved in manufacturing. The next round of skilled manufacturing workers are being developed here.

There are camps scheduled for spring break and right after the semester ends, in May.

What’s the most rewarding part of your job?

Chris: Working with students. Teaching them what I love to do.

Andy: I love it when a student has that lightbulb moment. When they think…“Now that thing I learned in class a year ago makes sense.”

We also love that Behrend emphasizes hands-on experiences. We hear back from friends in the field that Behrend students stand out on the manufacturing floors. One told us: “If I go into a shop and I see a student or young employee who is really sharp, I ask where they go to school—it’s almost always Behrend.”

What do you hope students carry with them from their time working with you?

Andy: We talk about life a lot. We tell them: The most stressful jobs make the most money. What is your life worth to you? How important is that money? Consider if you want to walk that walk.

Chris: We want them to understand that this is real. This is how things are made. This is how you solve problems. And we want them to know they can do it.

Andy: Manufacturing is such a noble thing. Man is meant to make things.