Penn State Behrend’s Class of 2024 is ready to make its mark on the world! We’re proud of our students and all that they have learned and accomplished here at Behrend. Over the next several weeks, we will introduce you to a few of our remarkable seniors who have engaged in college life in a big way, conducted valuable research, pioneered innovations, and overcome challenges during their time at Penn State Behrend.

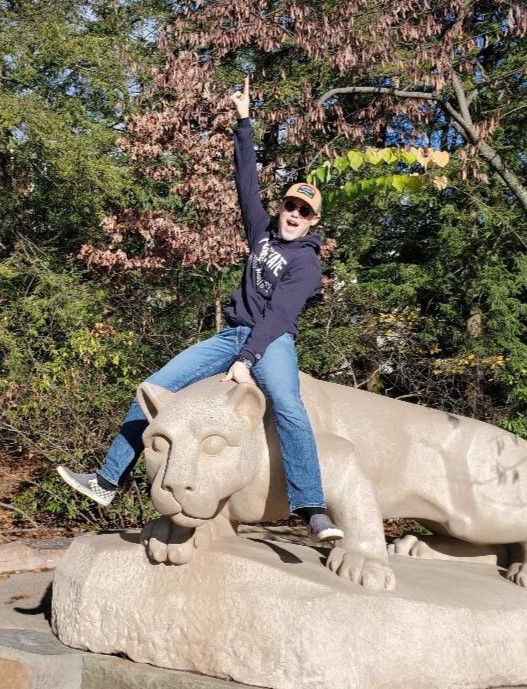

Today, we’d like you to meet Cameron Schmidt.

Major: Software Engineering

Minors: Game Development, Computer Science

Hometown: North Ridgeville, Ohio

On choosing Behrend: I chose Behrend for two reasons. The first was because of the Software Engineering program. I wanted Software Engineering over Computer Science, so I needed to find a school that had a good Software Engineering program, and after touring Behrend, I found it here. The second reason: Penn State. I was born and raised in Ohio, but grew up a Penn Stater because of my dad, who is a Penn State alumnus. During my childhood, if I was out with my dad and he was wearing a Penn State shirt there was always a chance we’d hear a ” WE ARE” from across a room, or I’d hear my dad suddenly yell “WE ARE” at other strangers wearing Penn State stuff. Complete strangers who he had never met before, connected simply by the fact that they went to the same school. Having that sense of community growing up made me realize early on that Penn State was special.

On choosing his major: I initially chose Computer Science, before I even decided where I wanted to go to school, simply because I wanted to make software applications. As I learned about the differences between Software Engineering and Computer Science, I ended up choosing Software Engineering, because unlike Computer Science, it also focused on Software Development concepts like documentation, design and implementation, project management, computer hardware, and more.

Campus involvement: While I was at Behrend I was mainly involved with one organization, Alpha Phi Omega, which is a co-ed service fraternity. I joined APO my second semester, mainly to make friends but soon began taking leadership positions in the group. APO really helped me develop my leadership skills, which helped me later when I became a resident assistant, throughout the rest of college, and in life in general.

A seat at the council table: I was also involved with an organization at University Park called the Council of Commonwealth Student Governments, or CCSG. For about three semesters, I served as the Associate Director of Student Affairs. My favorite part about my time in CCSG were the committee meetings. They gave me experience facilitating discussion among people, which I really enjoy.

People might be surprised to learn: I spent two summers at University Park, taking classes and working. The first summer, I just worked as an RA and took a few classes. The second summer, I worked as an RA and a Research Assistant and took quite a few classes. I have a lot of great memories from my time there, and gained a lot of academic, RA, and life experience!

His definition of living a good life: A good life is a life that is filled with little stress, less problems, where you have financial stability, and are doing what makes you happy. I want to emphasize the last point: do what makes you happy, only you know what that is and only you know how to achieve it.

HIs passions: I am passionate about learning and not just in an academic sense. I like learning about people and where they come from, what they’re passionate about. I also like learning about subjects completely unrelated to my field.

Advice for first-year students: The most important thing I think first year students should know is that it’s ok to mess up. Learn from your mistakes instead of letting them consume you. In my first semester, I failed two classes, got a D in two, and late-dropped one. It was really hard, but I learned from what I did wrong and came back from it. Another big piece of advice is to surround yourself with good people who will support you when you’re down, people you can learn from, and people who will help you grow as a person. That person for me in my first year and now, is my friend Ben Coler. I hope everyone can find someone like that.

After his graduation in May, Cameron plans to find work as an engineer in the game development industry, with hopes of eventually transitioning to game design and/or game production.